Author: Shiao Wu ab1, Yang Li b1, Yueming Li c, Fuyuan Zheng b, Zhongyi Zhao a, Xiangqing Kong d, Guorui Zhao b

Journal: Vacuum

DOI: https://doi.org/10.1016/j.vacuum.2025.114402Get rights and content

Abstract / 摘要

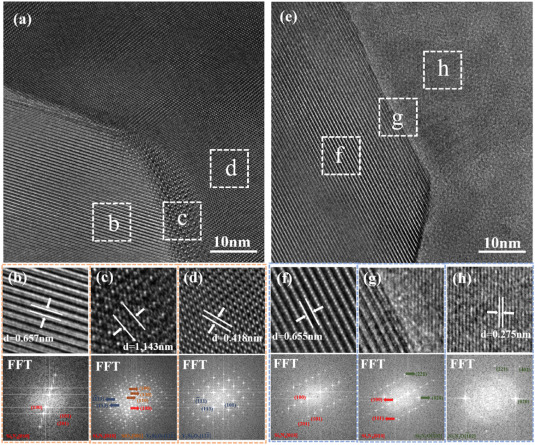

Preparation Si3N4 ceramics with high hardness and high fracture toughness is a challenge. In this work, Si3N4 ceramics with high hardness (18.35 ± 0.40 GPa) and high fracture toughness (8.54 ± 0.26 MPa m1/2) were obtained by in-situ nitriding of Si and Y powders and hot-press sintering. By controlling Y content, Si3N4 powders with different α-Si3N4 ratios were obtained, which in turn regulated grain size and morphology of Si3N4 ceramics after sintering. Addition of Y introduces Y-Si-O-N crystalline phase into nitrided powder, which transitions to Y2Si2O7 during subsequent sintering. Y2Si2O7 phase reduces bulk hardness but introduces residual stresses at interface, promotes grain elongation, and improves fracture toughness through crack bridging, stretching, and crack deflection mechanisms. In addition, atomic-scale microstructural analysis reveals coherent interfaces were formed between both Si3N4/SiO2/Y2Si2O7 as well as Si3N4/Si2N2O, with crystallographic orientation relationships of (100) Si3N4//(100) SiO2//(−111) Y2Si2O7 and [010] Si3N4//[001] SiO2//[12–1] Y2Si2O7 as well as (100) Si3N4//(020) Si2N2O and [010] Si3N4//[−102] Si2N2O. These in-situ generated coherent interfaces significantly enhance mechanical properties and reliability of samples, ensuring both high hardness and high fracture toughness.

Keywords / 关键词

Si3N4; Nitridation process; Hot-press sintering; Mechanical properties