Author: Xiujuan Chen, Yueming Li, Guorui Zhao

Journal:Ceramics International

DOI:10.1016/J.CERAMINT.2022.09.253

Abstract / 摘要

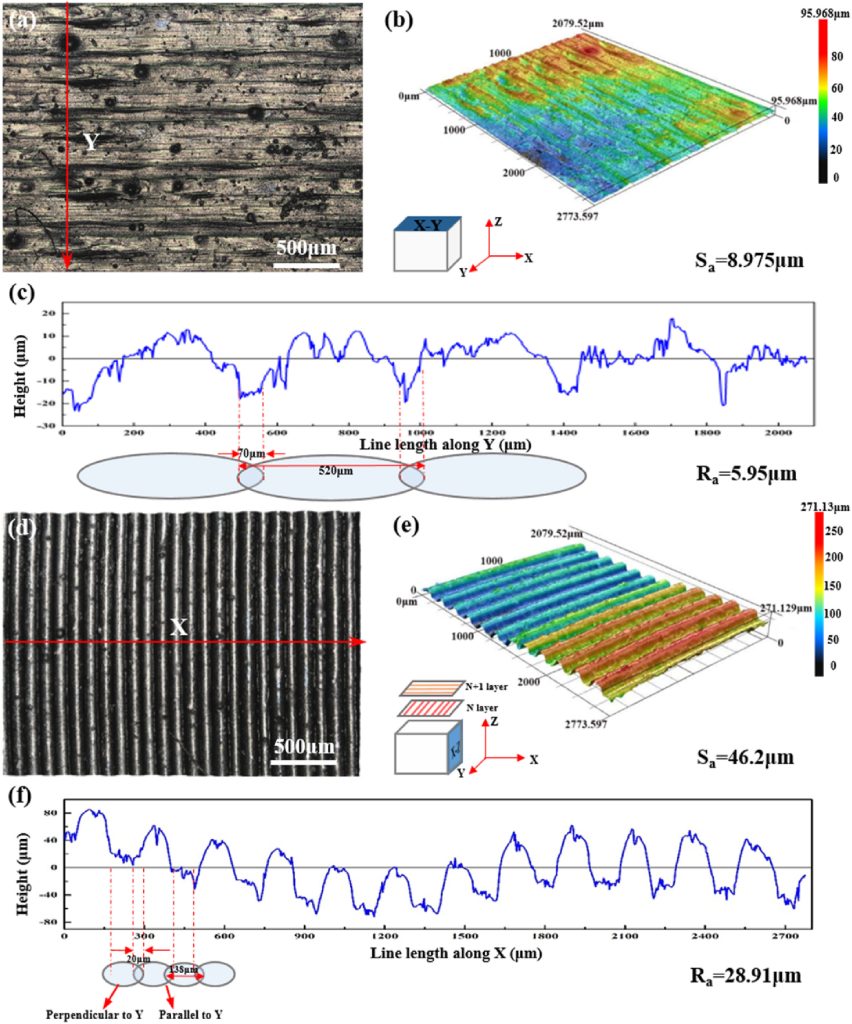

High density zirconia (ZrO2) parts with 3 mol% yttrium oxide (3Y-TZP) have been successfully fabricated using a novel additive manufacture technology of powder extrusion printing (PEP). The optimized parameters for the PEP fabrication of ZrO2 ceramic parts were determined with the orthogonal experiment. The microstructure, phase evolution, surface quality and mechanical properties of the as-prepared ZrO2 ceramic parts were systematically characterized and analyzed. The high density (98.6%) ZrO2 part was composed of submicron cellular grains without any discernible pores and cracks. The XRD analyses showed that the phase of sintered specimen was t-ZrO2. TEM results revealed that the grains of t-ZrO2 exhibited irregular polygonal morphologies with clear trigeminal grain boundary and minor m-ZrO2 existed with dislocation and stacking faults. Affected by the printing dimensions, the samples showed anisotropic character of surface quality, with the roughness of 9 μm and 46 μm for the horizontal (X–Y) and vertical (X-Z) surfaces, respectively. The compressive strength was also anisotropic with 1088.7 ± 241.8 MPa and 850.8 ± 110.8 MPa for the X–Y and X-Z surfaces, respectively. Additionally, the hardness and flexural strength of parts were 1486 ± 87 HV and 495 ± 11.8 MPa, respectively. Finally, a series of ZrO2 parts with complex geometries were produced to demonstrate the capability of PEP for fabricating geometrically complex ceramic parts.

Keyword / 关键词

Powder extrusion printing;Zirconia;Microstructure;Surface roughness;Mechanical properties