Author:Chaona Liu abc1, Li Tian c1, Yueming Li d, Fuyuan Zheng c, Yunhui Li b, Qingming Xu b, Jianwei Zhu b, Wenfei Li ab, Guorui Zhao c

Jurnal:Composites Part A: Applied Science and Manufacturing

DOI:https://doi.org/10.1016/j.compositesa.2025.109527

Abstract / 摘要

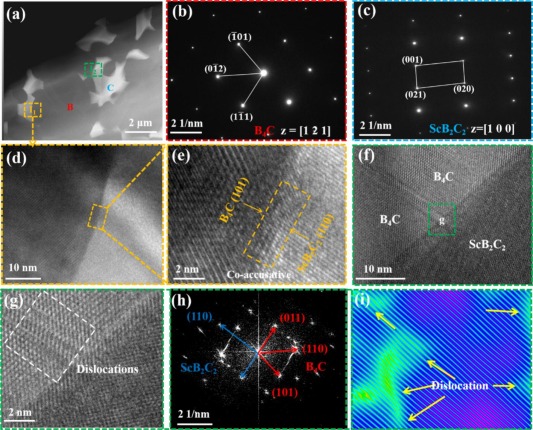

This work overcomes the long-standing brittleness and poor machinability of B4C by in-situ introduced conductive ScB2C2 network via reactive hot-pressing. The optimized composite containing 20 vol% ScB2C2 (BS-20) achieves a record fracture toughness of ∼ 10.5 MPa·m1/2—over twice that of monolithic B4C—enabled by residual stress fields from thermal-expansion mismatch and atomically coherent interfaces that promote crack deflection and bridging. Simultaneously, the percolating ScB2C2 network enables a semiconductor-to-conductor transition (∼ 0.65 × 103 S/m), thereby unlocking electro-discharge machining of complex geometries, a critical advance for practical deployment. Furthermore, the BS-20 composite demonstrated exceptional laser ablation resistance, sustaining high power densities (up to ∼ 1.6 × 107 W/cm2) without catastrophic failure, due to enhanced mechanical properties, energy dissipation and protective oxide scale formation. This work introduces a new class of damage-tolerant, electro-machinable, and laser-resistant B4C-based composites, establishing a generalizable strategy for designing multifunctional ceramics capable of reliable performance in extreme environments spanning aerospace, defense, and precision engineering.

Keyword / 关键词

Boron carbide; In situ reaction; Thermopressed sintering; Rare-earth ternary layered ceramics