Author:Jie Yang abc1, Hao Zhang c1, Yueming Li d, Zhongli Zhu ab, Yunhui Li ab, Qingming Xu ab, Guorui Zhao c

Jurnal:Journal of Alloys and Compounds

DOI:https://doi.org/10.1016/j.jallcom.2025.185127

Abstract / 摘要

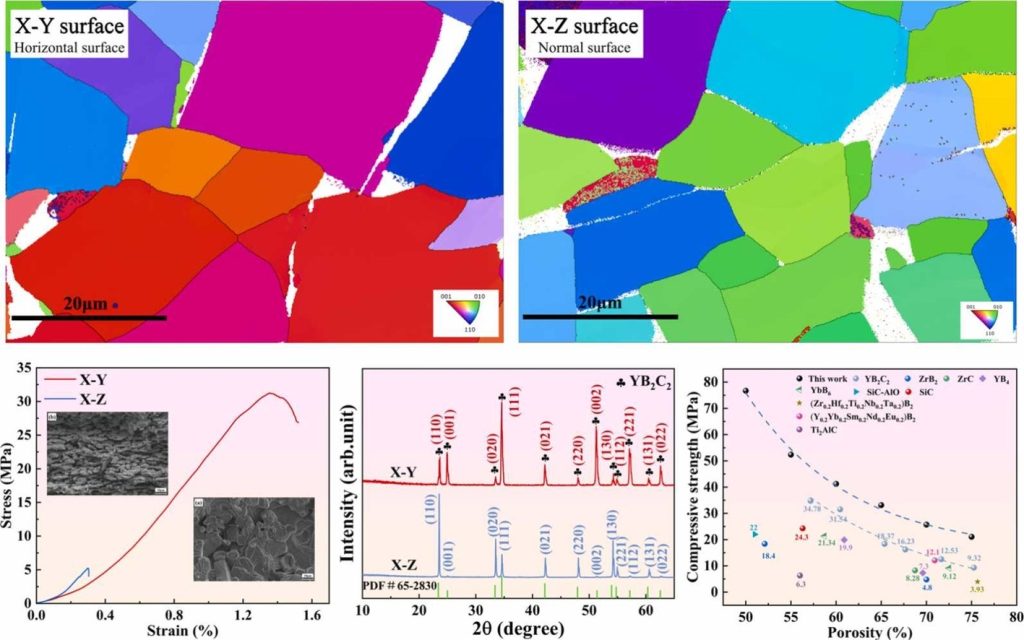

Controlling crystallographic texture and pore architecture in porous ultra-high temperature ceramics is critical for tailoring their performance in extreme environments, yet achieving this dual control remains a formidable challenge. Here, we demonstrate a novel strategy to fabricate architected porous YB2C2 ceramics exhibiting strong crystallographic and mechanical property anisotropy by synergizing powder extrusion printing with in-situ reaction synthesis. The core of our approach is a templated-growth mechanism, where shear forces during extrusion align sacrificial graphite flakes within the green body. These aligned flakes subsequently serve as heterogeneous nucleation and growth sites for plate-like YB2C2 grains during boro/carbothermal reduction, effectively translating the macro-scale printed path into a micro-scale crystallographic texture. This process yields a remarkable hierarchical structure, featuring unidirectionally aligned pores and a strong [001] crystallographic texture parallel to the printing direction. The resulting ceramics exhibit a highly tunable porosity (50–75 vol%) and exceptional compressive strength, reaching 76.7 ± 14.7 MPa at ∼50 % porosity. Crucially, this microstructural control imparts a pronounced mechanical anisotropy, a key attribute for designing components with directionally dependent loads. This work establishes a new paradigm for manufacturing ultra-high temperature ceramics, enabling the concurrent design of geometry and crystallographic texture to achieve tailored thermomechanical properties.

Keyword / 关键词

YB2C2; Porous ceramics; Anisotropy; Powder extrusion printing; Additive manufacturing